How is the Non-Stick Coating Stuck on to Kitchenware?

How do you get something that’s main purpose is to not stick, stick to something ?

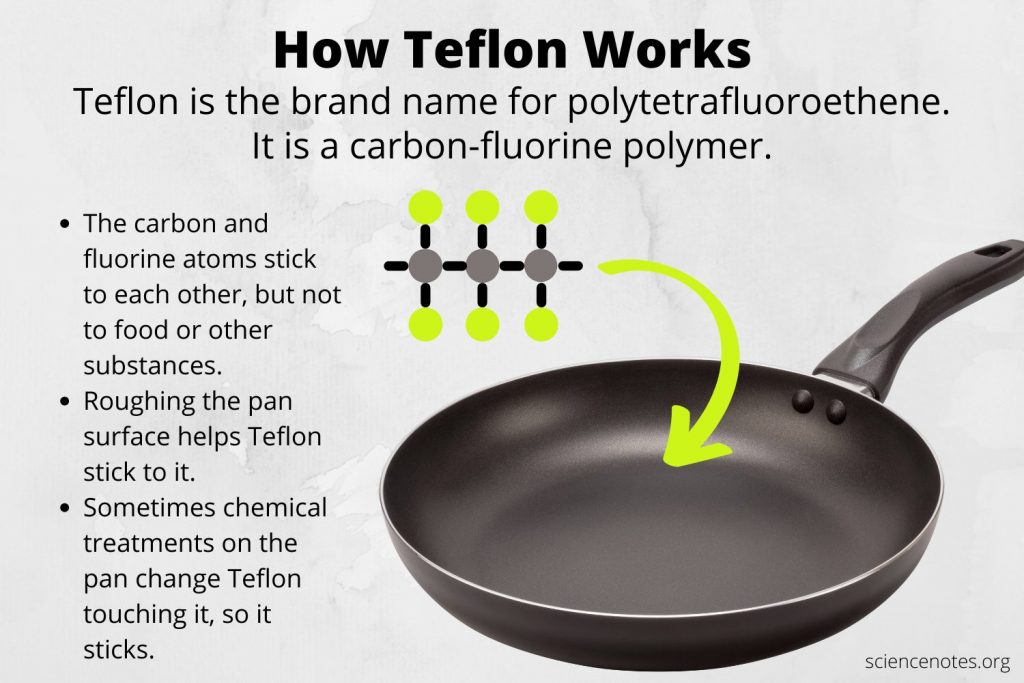

Discovered in 1938, by the American chemist Dr Roy Plunkett of the DuPont Company, polytetrafluoroethylene (PTFE) – Teflon, to use its commercial name – is famed for its non-stick properties.

It is also incredibly stable and non-reactive, resisting acids, alkalis, heat and solvents. All this is wonderful until one comes to actually using the stuff as a coating, when its chemical stubbornness becomes a liability.

The date … is significant … giving the lie to the only useful thing to come out of the Apollo programme being the non-stick frying pan

The problem of getting PTFE to stick to metal surfaces was solved in 1954, by Louis Hartmann. He used acid to etch tiny holes in the surface of the metal, then applied a layer of PTFE and baked it at 400°C. The melted PTFE seeped into the holes and solidified, pinning the coating to the surface.

The date of Hartmann’s work is significant: 15 years before Armstrong and Aldrin stepped on to the moon – giving the lie to that old saw about the only useful thing to come out of the Apollo programme being the non-stick frying pan.